The History of Strand Art

Established in 1974, Victor Strand, an electrical engineer at Autonetics, created Strand Art in his garage. He wondered “why do I have this dealership frame on my car?” He looked into purchasing novelty frames from a metal frame manufacturer and there it began, Strand Art Company. Offering in excess of 100 sayings, Victor hired neighborhood teenagers to drive his wares to seven local swap meets and BANG…there it was…a business.

It was a nice little business, it kept neighborhood kids employed as they were paid a penny a frame to transfer the frame from a paper bag to a poly bag. I mean, come on, the older kids were fast enough to do 100 frames per hour…a quick, easy dollar. But, as things grew, Peggy Strand had enough of the in-house venture, it was time for a shop. The first at 350 E. Orangethorpe, Suite H.

But, there had to be more. As an electrical engineer, Victor studied the concept and created the design for a raised copy plastic frame. In 1978, he designed his winner…a raised copy plastic frame called the 12 Style. Why the 12 Style? Well, it had one color decoration (black frame with white copy) and 2 holes. Soon to follow would be the 22 style – two color decoration (black frame, white painted background, colored copy) with 2 holes. This was really becoming a business. We still have our dies from our first two orders, “Kentucky Fried Chicken/Sizzler” and “Crossroads Chevrolet.” They were off and running.

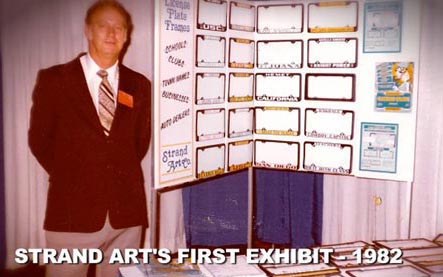

Victor always felt there were two ways to establish sales, either sell direct to the end user or join a sales organization where you manufacture for others. Victor picked the later. Becoming a member of ASI and PPAI in 1980, Strand Art Company became an ASI Supplier, showed their wares, and waited for orders.

Victor always felt there were two ways to establish sales, either sell direct to the end user or join a sales organization where you manufacture for others. Victor picked the later. Becoming a member of ASI and PPAI in 1980, Strand Art Company became an ASI Supplier, showed their wares, and waited for orders.

For the next several years things went well. Large distributors recognized the product line and ordered custom plastic frames as needed. The office grew from Suite H to Suite H & I. Vic, you’re paying rent on almost 3,000 square feet, how much further could this empire possibly grow?

The Plastic frame business went well, but there was one more step needed to reach desired success…becoming a metal license plate frame manufacturer. There were the giants, La France/Benmatt, D-line, and the smaller Robert Brown Co. It would be a tough little transition, but Victor wanted to make the move and started looking. Somehow he ran into Carol Fryer, owner of FC Enterprises in Monrovia, California.

FC was a smaller manufacturer of metal frames. Carol was getting up in age and needed a little help. After productive meetings, an agreement was made and Strand Art Company purchased the assets of FC Enterprises in 1994, instantly becoming a license plate frame manufacturer in both plastic and metal. This was a pretty big deal. Victor learned everything he needed to as it was now a necessity…he owned the stuff. But, it soon became very obvious that manufacturing metal is very different than manufacturing plastic.

The Plastic frame business went well, but there was one more step needed to reach desired success…becoming a metal license plate frame manufacturer. There were the giants, La France/Benmatt, D-line, and the smaller Robert Brown Co. It would be a tough little transition, but Victor wanted to make the move and started looking. Somehow he ran into Carol Fryer, owner of FC Enterprises in Monrovia, California. FC was a smaller manufacturer of metal frames. Carol was getting up in age and needed a little help. After productive meetings, an agreement was made and Strand Art Company purchased the assets of FC Enterprises in 1994, instantly becoming a license plate frame manufacturer in both plastic and metal. This was a pretty big deal. Victor learned everything he needed to as it was now a necessity…he owned the stuff. But, it soon became very obvious that manufacturing metal is very different than manufacturing plastic.

Plastic vs Metal

While plastic frames aren’t easy, they are much easier than metal. For plastic we would use four steps: 1) Engrave a die out of aluminum, 2) injection mold the needed number of parts, 3) hot stamp the copy color, and 4) place 260 frames in a box. Metal frames are a much longer process. 1) engrave a die in steel, 2) die cast your needed number of frames in 850 degree molten zinc, 3) use a trim press to eliminate all excess metal from the casting, 4) sand part as needed, 5) run frames through a vibratory machine to eliminate sharp edges, 6) chrome plate frames, 7) hand paint background color, 8) hand roll copy color, 9) bake frames at 350 degrees to cure all paint & inks, 10) individually bag and seal each frame, and finally 11) wrap in protective newspaper and place 60 per box.For the next 18 years, and currently, Strand Art Company is proud to say it considers itself the only true domestic manufacturer of metal license plate frames. While we are openly more expensive than imports, the reasoning is obvious when looking at global salaries. Overseas makes a nice product, the only problem is the 14 week delivery due to shipping. Strand Art Company depends on:

While plastic frames aren’t easy, they are much easier than metal. For plastic we would use four steps: 1) Engrave a die out of aluminum, 2) injection mold the needed number of parts, 3) hot stamp the copy color, and 4) place 260 frames in a box. Metal frames are a much longer process. 1) engrave a die in steel, 2) die cast your needed number of frames in 850 degree molten zinc, 3) use a trim press to eliminate all excess metal from the casting, 4) sand part as needed, 5) run frames through a vibratory machine to eliminate sharp edges, 6) chrome plate frames, 7) hand paint background color, 8) hand roll copy color, 9) bake frames at 350 degrees to cure all paint & inks, 10) individually bag and seal each frame, and finally 11) wrap in protective newspaper and place 60 per box.For the next 18 years, and currently, Strand Art Company is proud to say it considers itself the only true domestic manufacturer of metal license plate frames. While we are openly more expensive than imports, the reasoning is obvious when looking at global salaries. Overseas makes a nice product, the only problem is the 14 week delivery due to shipping. Strand Art Company depends on:

- Small minimums (minimum of 50 pieces on metal frames)

- Quick delivery (three week production on metal frames)

- Good quality…all at a fair price!

While we aren’t perfect, we will always make a sincere effort to reach a distributors and end users expectations. So, as questions might arise, we’d ask that you’d simply call and ask. We are open Monday – Friday, 6:00 am to 5:00 pm (PST).

While we aren’t perfect, we will always make a sincere effort to reach a distributors and end users expectations. So, as questions might arise, we’d ask that you’d simply call and ask. We are open Monday – Friday, 6:00 am to 5:00 pm (PST).

800-233-8558

Thank You